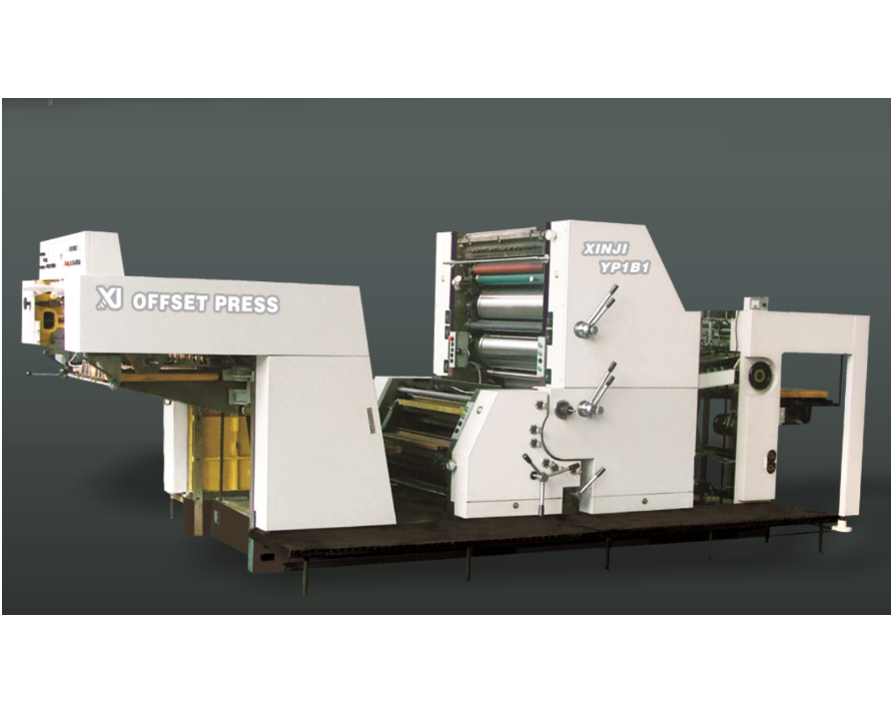

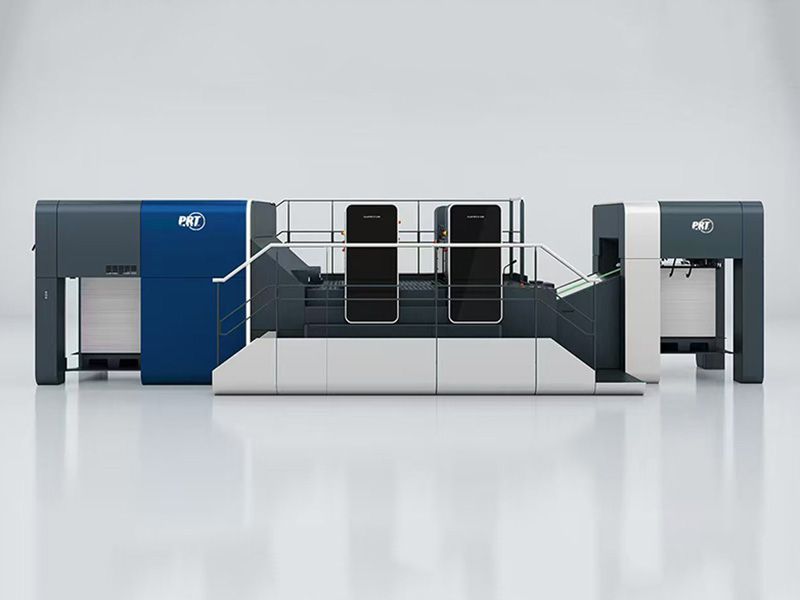

ITEM | YP2B1K (two color)

|

Max.sheet size | 720×1040mm |

Min.sheet size | 360×520mm |

Paper thickness | 30-450g/m2 |

Max.printing area | 710×1040mm |

Plate size | 800×1050×0.3mm |

Blanket size | 910×1060mm |

Covering size | 830×1040×1mm |

Maximum speed | 10000s/h |

Feed paper pile height | 1060mm |

Delivery paper pile height | 910mm |

Main motor power | 11kw |

Niet weight | 10800 |

Overall dimensions | 6209×2987×2176mm |

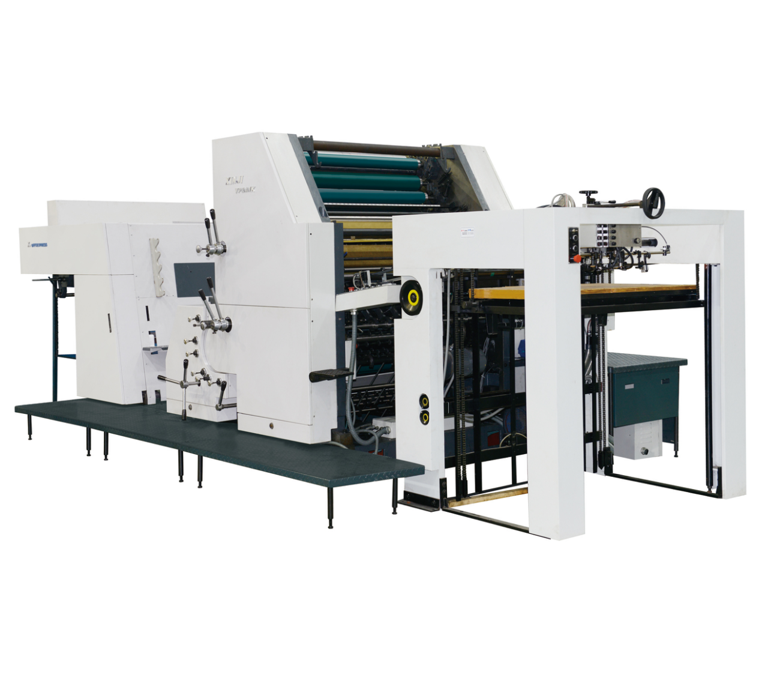

1. 输纸部分 Paper feeding part

Feeder paper conveyor adopts European popular structural design, with high speed and stability. Perfect combination of machinery, electricity and gas, stable operation; Accurate paper feeding and high precision; Compact structure and convenient adjustment and operation; The detection action is sensitive and reliable;

The enclosed shield of the whole machine is beautiful and generous; The paper feeding bridge plate frame can be lifted and lowered manually, which is convenient for adjustment.

2. 套准机构 Registration mechanism

Swing paper delivery mechanism, the machine runs smoothly;

The front and rear height gauges can be adjusted separately; Electric teeth detect paper faults such as empty sheet, double sheet, early arrival, late arrival and skew of paper;

The side rules can be moved as a whole or adjusted slightly;

3. 印刷部分 Printing part

The embossing, rubber and plate cylinder are supported by hollow roller bearings (Chinese national patent No.: ZL 022 84558.5), preloading eliminates the gap, and the machine runs light, stable and high precision

The plate clamp structure adopts fast clamping mode, which is convenient and simple, shortens the printing preparation time and improves the work efficiency;

The embossing roller is sprayed with wear-resistant and corrosion-resistant hardened layer; Greatly improved durability

The paper biting teeth are high, the teeth are closed, and the paper biting is stable

Alcohol fountain system can be equipped to improve the quality and grade of printing materials.

Equipped with deinking device to improve operation safety

4. 匀墨及给水部分 Inking and water supply

The ink transmission structure is similar to the European model design, with fast ink transmission and uniform ink channeling;

The eccentric mechanism can adjust the amount of ink channeling roller and water channeling roller, which can realize stepless adjustment;

The outlet roller motor is driven by frequency converter with stepless speed regulation, and the water volume can be adjusted flexibly

The automatic circulating water feeding device / alcohol fountain model has bright ink color and is conducive to registration.

5. 收纸部分 Paper receiving part

The auxiliary paper receiving mechanism changes the paper stacking table or paper drying rack without stopping the machine;

The powder spraying device is suitable for printing coated paper and large ink printing;

Paper receiving fan unit, suitable for high-speed printing;

The paper receiving opening die can adjust the travel and stay position according to the running speed of the machine;

The paper brake roller can adjust the position according to the paper size;

Brake roll suction device, adjustable suction volume, flat paper;

The position of the side flush paper baffle shaft can be adjusted according to the size of the paper;

6. 润滑系统 lubrication system

Circulating throttle type automatic centralized lubrication system, regular and quantitative oil supply lubrication;

Fault detection and alarm of random lubrication system;

PC controls the oil supply time and quantity;

7. 控制系统 Control system

Programmable controller and Chinese character display, reliable performance and high degree of automation;

The main motor is a variable frequency speed regulating motor, which can adjust speed steplessly and save power consumption;

Liquid crystal display alarm device, automatic fault display;

Set safety protection measures such as stop lock, safety bar, shield switch, manual turning switch and paper pile lifting limit switch;

Short circuit and overload protection function.